60 – 260 Tones VsP Series Simple, Productive, Economical

The innovative new servo motor with high efficacy gear pump system, achieves energy-saving operation and quick response equivalent to those of all electric injection molding machines.

- Energy saving-almost equivalent to all-electric model machine.

- Quick response-injection response time (Standard mode).

- Stability in low-velocity / low-pressure & wide range-injection velocity: From ultra-low to high velocity range.

- Linearity-Excellent linearity in both injection velocity and injection pressure.

- Excellent injection holding pressure performance-Capability in sustaining high injection holding press longer (as compared with full-electric machine).

- Reduction in the amount of hydraulic oil and cooling water volume.

- Silent (low noise gear pump operation) Almost equivalent to all electric injection molding machine.

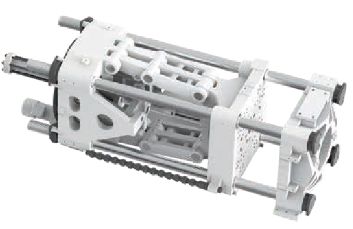

High Precision Injection Unit

The VsP Series optimum screw geometry plus the perfected drive and injection concepts provides excellent plasticizing and injection capacity. newly developed high wear and corrosion resistance ion-nitrated screw and barrel gives the customers a wide choice of materials for numerous applications. The gently prepared and properly homogenized melt is metered accurately, shot after shot, and is injected into the mold with high power and high speed

The screw and barrel used on the Fortune machines has the following properties.

- Injection screw ACM2 German material

- Surface hardness: 900 ~ 1100 HV

- Processed by Nitride (500 ~ 520 °C for 72 hrs)

- Nitrided thickness: 0.4 ~ 0.5 mm

Bi-metallic casting screw and barrel (Option) – SKD 61 base material. Excellent wear-resistant, corrosion resistant screw & barrel for the processing of materials with fiber additives and also fire retardant material.

The multi-notch locking style screw tip. The locking style tip is useful for stabilizing part weight and increasing product precision comparing the convectional screw tip. The gap between the screw and check ring is reduced to the least, thereby the back flow resin can be reduced to minimum.

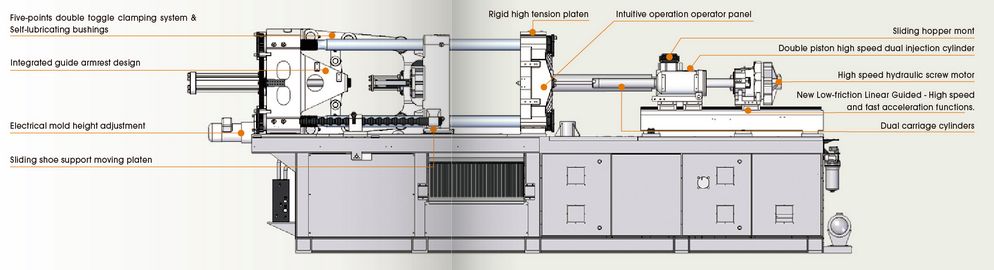

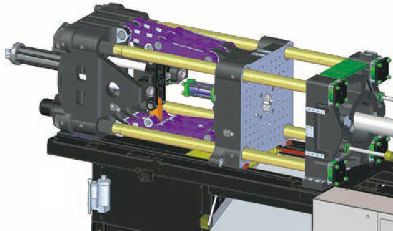

Heavy Duty, Rigid, Clamping Unit

Every component in the clamping unit that is subjected to a mechanical stress was designed and checked using the F.E.M. (Finite Element Method) of structure analysis. All VsP Series machines feature a unique, ultra-reliable, five-point toggle clamping mechanism, which is characterized, by an almost ideal kinematic velocity feature. This system has fast speed, high force ratio, sensitive mold protection and good energy saving capabilities. The large square cast iron platens are extremely robust and the widely spaced tie bars allow for even the most complex of molds.

Mold height adjustment, which is the bull gear system, is operated by an electrical brake motor and when co-ordinates with a precision circuit breaker proceeds to prevent the possibility of overloading by force and cause machine damages.

Material:

- Platen: Meehanite casting FCD 55

- Tie bar: NH48MV (from Japan)

- Toggle pin: SCM440 (hard chrome plating)

Advantage:

- Machine life ~ 15 years and more

- Eliminates the oil pollution

- Saves maintenance time