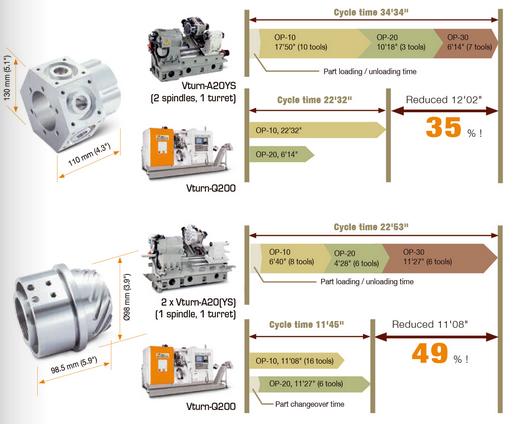

Vt-Q200

- Minimizing the cutting time difference between OP-10 and OP-20 to balance cutting tempo and maximizing the turning length on twin-turret lathes when deep hole drilling is required.

- Offering sufficient 32 tools for both OP-10 and OP-20 machining applications at quicker tool exchange compared as multi-tasking lathes with ATC.

- Used as traveling steady reset, work rest or tailstock for more flexible applications.

- Turning slender shafts or drilling/tapping the symmetric holes with upper turret simultaneously (“balanced cutting”)

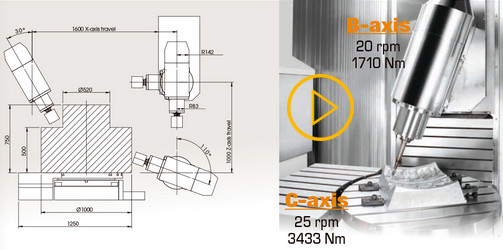

Vc-AX800

- Swivel head (B-axis) and rotary table (C-axis) facilitate 5-axis machining of large parts, up to 1000mm indiameter.

- C-axis table is clamped at high torque 3433Nm for heavy cutting.

- The B-axis swivel head includes a Hirth coupling with 1″ increment further enhancing the rigidity, and 4 + 1 axis machining capability.

- BBT-40 spindle 15000rpm (22kW).

Vc-AX630

- Traveling column VMC coped with trunnion type rotary table (630 x 500mm) implements 5-axis machining on middle size part at compact floor space.

- Tilting table is seated on the machine base for high rigidity.

- Roller type linear motion guide-ways.

- High rapid feed 48m/min, high speed BBT-40/12000rpm spindle and high rotary speed minimizes overall cycle time.

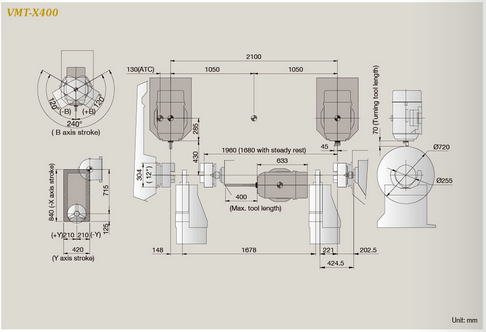

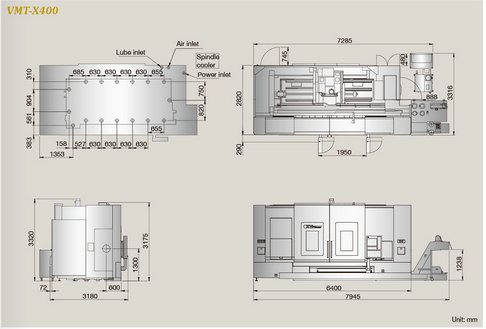

VMT-X400

Machine Range

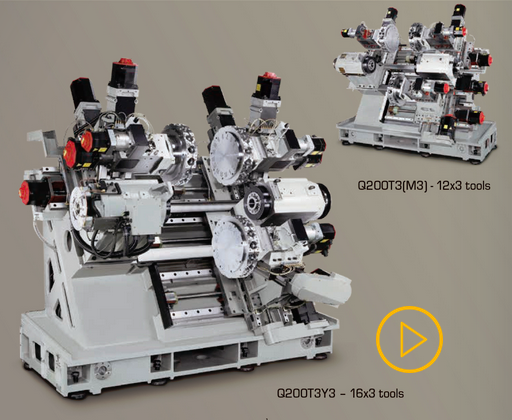

Machine Layout

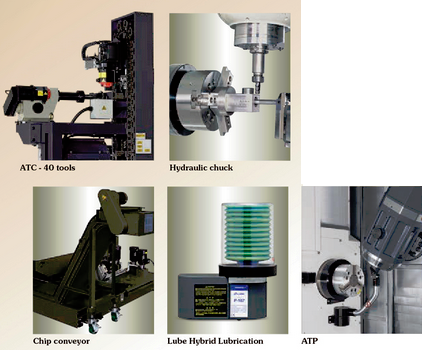

Standard Accessory