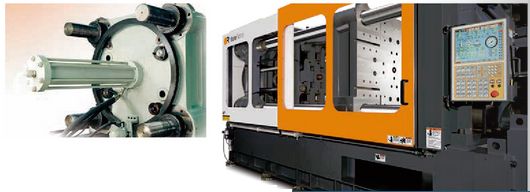

Bi-metallic material (optional) – SKD 61 base material. Excellent wear-resistant, corrosion resistant screw & barrel for the processing of materials with fiber additives and also fire retardant materials. Fortune general purpose screw and barrels can process any kind of material like PE, PP, PA, ABS, AS. We also supply an optional screw & barrel for engineering materials like PC, PBT, PET, with an L/D ratio from 18, 20, 22.

- Injection screw ACM2 German material

- Surface hardness: 900~1100 HV

- Processed by Nitrite (500~520° C for 72 hrs)

- Nitrated thickness: 0.4 ~ 0.5 mm

- Piston rod uses S45C steel which has excellent strength

- Piston seal uses German make Merkel to reduce the leakage and extend piston life.

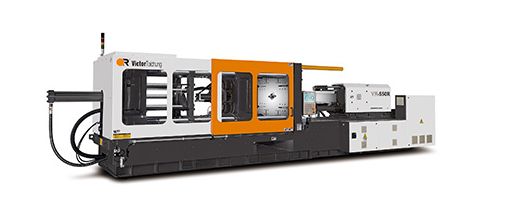

The VR Series injection unit, utilizing the high wear and corrosion resistant ion-nitrided screw and barrel, provides the injection volumes and plasticizing capacities necessary for the manufacture of precision products. With high injection stability and excellent mixing capabilities, this newly developed injection unit allows for the use of a wider range of materials.

Heavy Duty, Rigid, Clamping Unit

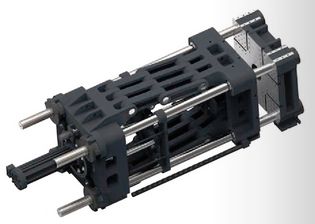

All VR Series machines feature a unique, ultra-reliable, five-point toggle clamping mechanism which is characterized by an almost idea kinematic velocity feature.

This high precision clamping unit is designed and analyzed using the latest in computer software, CAD & CAE. The large cast iron platens are extremely robust and with widely spaced fle-bars to accommodate the largest of molds. They have optimum rigidity that matches the current need in precision molding and which minimizes mold deflection caused by clamping force and cavity pressure.

The large, square coast iron platens virtually eliminate deflection. The bushings are manufactured from graphite impregnated phosphor bronze. Designed to run totally oil-free. there’s no chance of contaminating molds, and maintenance is limited to long periodic greasing.

Mold height adjustment, which is the bull great system, is operated by a hydraulic motor and when co-ordinates with a monitoring program proceeds to prevent the possibility of overloading by force and cause machine damage.

Material:

- Platen: Meehanite casting FCD 55

- Tie bar: NH48MV (fom Japan)

- Toggle pin: SCM21 (hard chrome plating)

Advantage:

- Machine life ~ 15 years more

- Eliminates the old pollution

- Saves maintenance time